Enumerate and Explain Different Types of Lathe Machines

Special Purpose and. Vertical Turret Lathe and.

Do You Know What Are The Different Types Of Lathe Machine Machine Future Machinery Future Machine Tool Industry All In Here

Usually grooves are cut on a cylindrical surface in narrow shape by means of grooving tool.

. The various other operations that you can perform with the help of Lathe. Different types of chucks. The lathe machine tools can be classified into different categories.

These are probably the most popular among the. Following are the Lathe machine operations done either by holding the workpiece between centres or by a chuck. The cutting edge of grooving tool is kept narrow.

Right-hand tool left-hand tool round hose tool. These types of lathe machine are the same with the engine lathe but has some extra features. Turning is the most common lathe machining operation.

Lathe machine has been categorized into the following types. The most common lathe operations are turning facing grooving parting threading drilling boring knurling and tapping. T-shape lathe are used to machine rotors used in jet engines and gas turbines.

Lathe Machine on a Bench Lathe Machine in the Toolroom Machine with a capstan and a turret. 74 Compound rest method. There are many types of lathes.

The vertical turning centers are used. The turret lathe is another metalworking machine but this is built specifically for mass production. Each of these lathes has specific applications and distinctive characteristics.

Automatic lathe is known for their enhancement in quality and the quantity of production. There are three general types of lathe machines which are engine lathes turret lathes and special purpose lathes. Engine Lathe or Center Lathe.

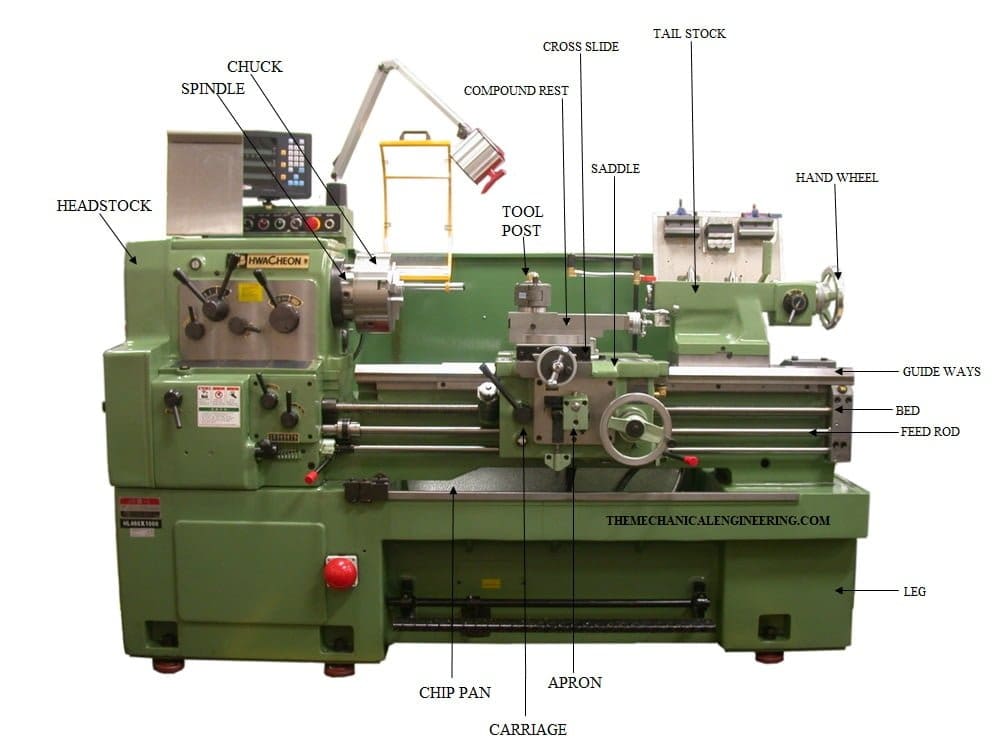

The seven distinct types of lathe machines are as follows. High-speed steel tool carbide tool diamond blade other materials etc. The eight primary parts that make up a lathe machine include.

Thread Cutting on Lathe -Lathe Machine Operations. The CNC lathe and turning centers are a kind of high precision and high-efficiency automatic machine tool. 731 Advantages of tailstock set over method.

The variation of tool ends and a kinematic relation between the tool and workpiece results in different operations on a lathe. Types of Lathe Carriers. Method of applying feed.

Center or Engine Lathe. Wheel lathe is used for machining of journals and rail rods. Gap bed lathe is used to machine large diameter work piece ie.

Tool Room Lathe. Thread cutting on lathe Machine. 732 Disadvantages of the tailstock set over method.

This guide will help you to familiarize the parts of a CNC lathe turning center and what are types of lathe machine. The direction of the movement of the cutting tool is actually controlled by the operator. Machine for turning engines.

Parts of Lathe Machine Diagram. According to the type of drive the lathes can be grouped as. The carrier or dog is a work holding devices in lathe machine used to hold a job when it needs to be fixed between the centers.

CNC lathes are not one machine there are several types. 71 Form tool method A Taper Turning Operation. Types of Lathe Machine Operations.

This includes speed lathe engine lathe tool-room lathe special. Often the following types of lathe carriers are used. There are 10 different types of Lathe Machine and those are.

A lathe is a machine tool which is used to rotate a workpiece to perform various operations such as turning facing knurling grooving etc with the help of tools that are applied to the workpiece. Some of the types are CNC version of the manual lathes already discussed including CNC toolroom lathes CNC engine lathes and CNC turret lathes. Capstan and Turret Lathe.

7 Taper Turning Methods. Four Jaw Chuck-Three Jaw Universal Chuck-Air or Hydraulic operated Chuck-Magnetic Chuck-Collet Chuck-Combination Chuck-5. 72 Tailstock set over method.

Having step-cone pulley drive and. The lathe machine operations are classified into three main categories and are as follows. 73 A formula to calculate the tailstock set-over method To calculate the offset height.

They provide the same results offering the same benefits and have lower skill requirements to operate. We are going to study each and every important point of these 8 different types of lathe machines. Plain or Straight Turning.

Lathe Machines are used in metalworking woodturning metal spinning thermal spraying glass working and parts reclamation. Parts of lathe machine with diagram. The turning centers are two wind types they are horizontal turning center and the vertical turning center.

It is also used for turning the threads on locomotive wheels. The bed the base the headstock for rotating the spindle the tailstock for securing your tool bit the carriage your guide the. Different types of lathe machine and their classification Tool room lathe.

Lathe machine are of different types according the types of work performed. The most common classifications include. A lathe machine is a machine tool which is used to remove metals from a workpiece to give a desired shape and size.

Work or a job inserted into the hole of a carrier and then tightly fixed. This type of lathe eliminates many variables in the production process that could hinder the final product making mass production a possibility. This operation is also denoted as necking.

Lathe Machine Parts Names. So how many types of Lathe machines are there. Turning tool boring tool chamfering tool grooving tool etc.

Bent Tail Carrier. The way this lathe works is that multiple shaping tools are mounted on a saddle. Up to 15 to 2 meters and 6-8 meters in length.

Every single one of these key lathe machine parts serves a very important function that allows you to use a lathe machine for your desired purpose. Automatic Spindle Lathe Machine.

What Is Lathe Machine Types Of Lathe Machine Their Uses Complete Guide Engineering Learn

Lathe Machine Definition Parts Types Operation Specification Advantages Application Notes Pdf

Comments

Post a Comment